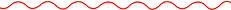

CHANNEL WHEEL

罐道轮为一种立井提升容器用滚轮罐耳

其结构由底座、摆转臂、滚轮、缓冲器组成;滚轮罐耳结合我国矿山特点为目前运行中的

提升容器更换新型滚轮导向装置提供了便利条件,

广泛应用与矿山,煤炭等工业生产部门。

矿山

MINE

煤炭

COAL

工业生产

INDUSTRIAL PRODUCTION

滚轮罐耳沿罐道运行时,因罐道的设计安装,会产生接点、弯曲高点,轮头会受到水平推力作用,由于支臂架、

底座和缓冲器之间的铰接作用,使缓冲器受压缩产生反弹力。

缓冲器的反弹力

一、保证提升容器顺利通过高点;

二、保证提升容器不得与罐道发生碰撞;

三、要保证提升容器在上升和下降过程中摆动幅度不得太大。

1、Ensure THAT THE LIFTING VESSELPASSES THROUGH THE HIGH POINT SMOOTHLY;

2、ENSURE THAT THE LIFTING CONTAINER DOES NOT COLLIDE WITH THE TANK CHANNEL;

3、IT IS necessary TO ensure THAT THE SWING RANGE OF THE ILFTING CONTAINER IN THE PROCESS OF RISING AND FALLING IS NOT TOO LARGE.

所以缓冲器的缓冲性能是严格按提升容器的重

量、运行速度进行设计的,但其轮头最大水平

推力一定要小于或等于行业标准的要求。根据

以上理论设计制造出的滚轮罐耳能够有效满足

用户要求。

罐道轮 型号参数

罐道轮的作用原理是滚轮受力通过支架、调节套、调节螺杆、碟簧轴施力于碟簧上,通过碟簧轴

上、下运动释放和压缩碟黄组实现缓冲。

The working principle of the channel wheel is that the roller is forced on the disc spring through

the bracket, the adjusting sleeve,

the adjusting screw and the disc spring shaft, and the buffer is realized by the up and down

movement of the disc spring shaft and

the compression of the disc yellow group.

| 型号 | 滚轮直径mm | 最大水平力KN | 缓冲行程mm | ||

|---|---|---|---|---|---|

| 单轮 | L25 | 250 | 12 | 10~14 |

|

| L30 | 300 | 16 | |||

| L35 | 350 | 24 | |||

| L42.5 | 425 | 33 | |||

| L45 | 450 | 35 | |||

| L50 | 500 | 36 | |||

| 双轮 | LS30 | 300 | 20 |

|

|

| LS35 | 350 | 28 | |||

| LS42.5 | 425 | 42 | |||

| LS45 | 450 | 44 | |||

| LS50 | 500 | 45 | |||

选择我们的优势

罐道轮的作用原理是滚轮受力通过支架、调节套、调节螺杆、碟簧轴施力于碟簧上,通过碟簧轴上、

下运动释放和压缩碟黄组实现缓冲。

The working principle of the channel wheel is that the roller is forced on the disc spring through

the bracket, the adjusting sleeve, the ad

justing screw and the disc spring shaft, and the buffer is realized by the up and down movement of

the disc spring shaft and the compres

sion of the disc yellow group.

STRONG IMPACT

RESISTANCE

NO.1

抗冲击性强

承载能力大、寿命长、调整维修方便;

底座等零部件采用新型材料,整体结构强度更

高抗冲击性强。

STADBLE OPERATION AND

MAINTENANCE FREE

NO.2

运行稳定、免维护

缓冲器复位压力小,可有效地避免滚轮与罐道

产生异常碰撞。通过杠杆传递 到减震筒上,同

时起到导向、缓冲与稳定作用。

LOW WEAR AND LONG

SERVICE LOFE

NO.3

磨损度低、使用寿命长

罐道与罐耳由滑动摩擦变为滚动摩擦,因此减

少了动力消耗,降低了噪音,罐道和罐耳的磨

损也大大降低。从而,提高了罐道和罐耳的使

用寿命。

故障分析及排除

滚轮端盖中心孔上安装有密封塞,同时端盖上设有通气孔,真正做到新油易入,

旧油易出。

The center hole of the roller end cover is provided with a sealing plug, and the end cover is

provided with an air vent, so that

the new oil is easy to enter and the old oil is easy to exit.

原因分析: 滚轮与罐道接触过紧

排除方法:缺少润滑脂调整滚轮接触到

罐道即可,不要加预紧力

1、原因分析: 摆架下铰链套磨损,间隙大

排除方法:更换新套及铰链轴

2、原因分析: 轴承游隙太大

排除方法:拆下副轮毂,用圆螺母调整

轴承游隙

原因分析: 轴承缺少润滑脂

排除方法:注入适量润滑脂